Canwest Concrete Cutting and Coring can handle your commercial concrete project from start to finish while removing your stress and delivering top-notch results.

Below we provide a 30,000 overview of concrete cutting.

Concrete cutting refers to the process of controlled drilling, sawing and removal of concrete. While jackhammers used to pulverize concrete in the past, this method caused much damage to concrete. Today, concrete cutting experts have cutting-edge tools and techniques to create top-notch results for commercial businesses.

Concrete Cutting Equipment 101

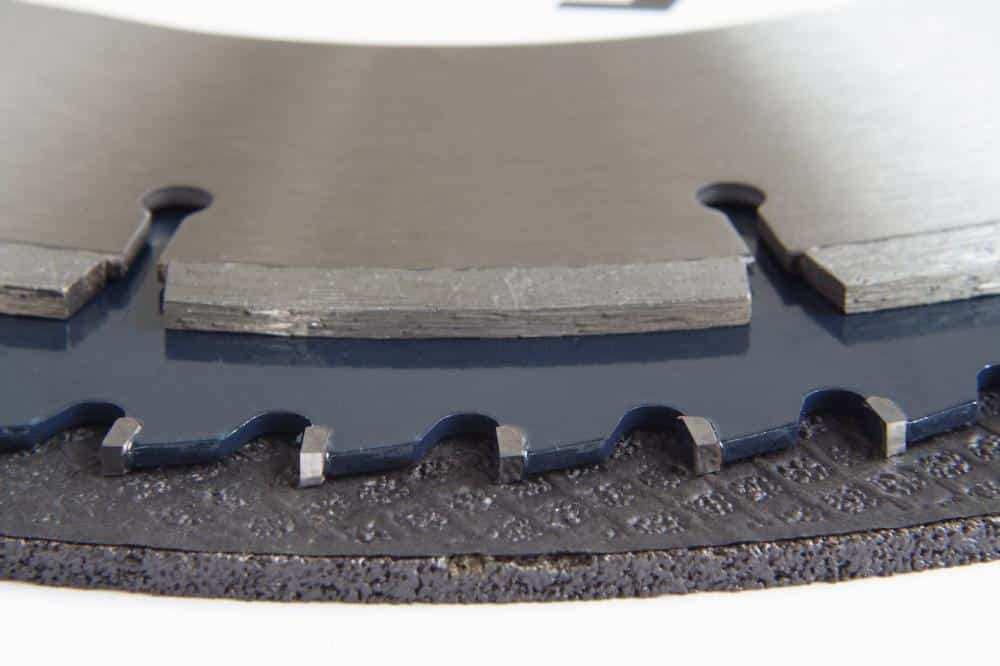

Concrete cutting tools are expert-operated saws with diamond blades or abrasive wheels. Concrete cutting saws can be powered by an electric motor, air compressor, hydraulic power unit or a two-stroke engine. It can help cut concrete and asphalt without a hassle.

Concrete polishing experts use diamond tools to give concrete and stone a smooth, modern finish.

Concrete Cutting Techniques

Here are some of the most common concrete cutting techniques:

Wall Sawing

Cutting concrete walls requires the use of track-mounted machines with circular blades. The track allows the saw to cut ceilings and climb walls. Using this method, skilled workers can cut concrete walls with a thickness between 16 and 36 inches.

Core Drilling

In this technique, a hole is drilled through concrete to create space for pipes, air conditioning vents, ventilation and wiring. Core drilling makes it possible to cut deep, circular holes.

Concrete core drills use steel tubes lined with diamonds to cut precise holes in concrete. The difficulty level is high, and experienced and trained concrete coring experts should perform core drilling.

Flat Sawing

Concrete slab sawing, sometimes known as flat sawing, cuts pavement, bridge decks and floors. Operators use cart-mounted saws for flat sawing. This method is popular when accessing wiring or pipes underneath concrete floors. Also, concrete slab sawing is paramount for cutting plumbing trenches and repairing highway roads.

Wire Sawing

Commercial concrete cutting experts count on concrete wire sawing methods reserved for more significant concrete cutting projects. Since it entails sophisticated machines requiring a high skill level, wire saws are used by concrete cutting experts.

A wire saw has a cable with diamond segments powered by a pulley hydraulic drive.

Different types of concrete cutting machines have their own set of advantages.

- Electric saws are easy to use, less noisy and lightweight. Hence, they are suitable for enclosed spaces.

- Hydraulic saws feature the highest power-to-weight ratio. Yet, they are costly and need considerable expertise.

- Pneumatic saws have fewer hazards than hydraulic saws, are easy to operate and more convenient due to the air compressor.

- Gas-powered saws are the most popular concrete cutting tool owing to their portability and low weight. But, they need more maintenance.

Conclusion

Commercial Concrete cutting is a challenging task. Best done by experts with today's best equipment. CanWest Concrete Cutting and Coring experts can manage your commercial project from start to finish.